| Speedys Guide to Benchrest |

| Written by © 2004 Speedco Shooting Sports, Inc. All rights reserved | |||

| 21 mars 2007 kl 20:30 | |||

Shooting Components

Reloading Equipment

Benchrest Management 101

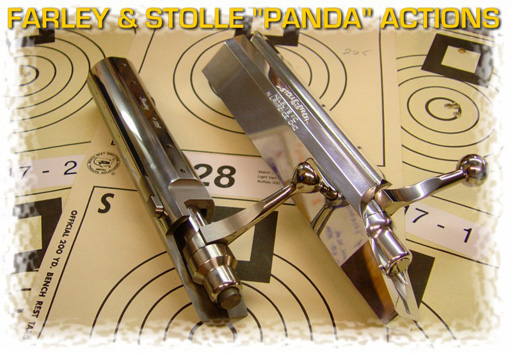

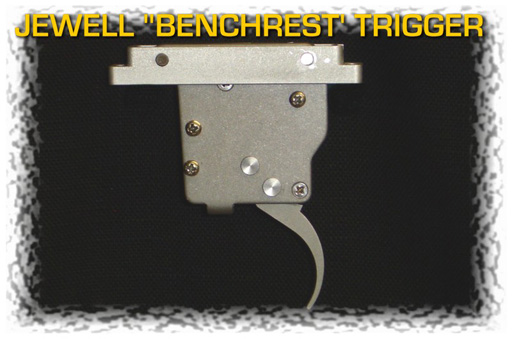

1. Rifles The differences between the three classes are spelled out below. The ”SPORTER” – In all respects, it is a clone to the 10.5 lb. ”Light Varmint” rifle. It is the only rifle that can be shot across the board in all three classes. The only restriction placed on the ”Sporter” is a caliber restriction. It must be of a 6mm caliber (0.2430) or larger. The ”HEAVY VARMINT” – In all aspects is identical to its lighter cousin with the exception that its weight can be pushed up an additional 3 lbs. This increase in weight makes the Heavy Varmint (HV) rig much easier to learn to shoot because its weight in the bag is much more forgiving when the shooter makes a gun handling error. The Heavy Varmints greatest asset comes into play when the conditions lay down and the matches turn into a ”Trigger Pulling” match. Those individuals who have a truly fine-tuned HV rig become very, very hard to beat. There are many different variations and thoughts as to what makes the ideal ”Action” for benchrest competition. The first universally accepted concept is the precise fit between all mating parts, while keeping them all in alignment with, or perpendicular to, the axis of the receiver. We will discuss some of the tips in achieving this concept to a higher degree a bit later in this section. The second concept is the material or combinations of materials from which the actions are manufactured. These are chosen by manufacturers for either their properties or for ease of manufacturing. Kelblys Inc., who is probably the number one supplier of high quality benchrest actions to the sport, offers the consumer two types of receivers. One, an octagonal designed receiver made from 7075 T-6 aircraft quality aluminum with chrome-molly steel inserts at all wear points where the barrel is threaded into the receiver. The advantage of this action is its large footprint for a better and larger bedding surface. It is also thought that the coefficient of expansion between the action and the scopes being made of the same material also enhances the overall performance of the BR rig. Another theory about the aluminum receiver is its dampening qualities, which aid in minimizing vibrations set up in the process of firing a BR rig. Kelblys Inc., Nesika Bay, Farley, Bat Machine and Hall Mfg. as well as a handful of others also manufacture a line of actions machined from billet or cast stainless steel. The types of stainless normally employed in their manufacture are 15-5 to 17-4 PH. These receivers offer corrosion resistance and greater longevity of tolerances over the life of the rifle. When polished to a mirror finish, these actions become a thing of beauty and are ”oohed” and ”ahhed” over by all who lay eyes on them. The last material still used on occasion is chrome-molly steel. This is the typical material used by most commercial manufacturers. They are usually distinguished by their bluish finish, but from time to time one may come across a C-M receiver finished in black ”Teflon” or electroless nickel. There is, however, some renewed interest being shown by some action makers and top-level shooters who feel that some of the best BR rigs they ever owned were made of the old standby chrome-molly steel. This will be played out on the BR ranges as they emerge onto the scene in the up-coming seasons. Benchrest actions today are also made to accommodate just about every shooters style of shooting. Whether right or left-handed or whether he or she is a slow deliberate shooter or a fast ”machine gun” style shooter, actions can be configured with right hand bolt and left hand port in order for the right-handed shooter to have a good view of the loading port and easy access to placing that next round directly into the chamber, without fumbling around blindly with a port opposite the shooter. Many modern day actions come equipped with an ejector that just lays the fired cartridge outside of the loading ports so as to not damage ones meticulously prepared brass. Today a competitor can choose an action to eject a fired case in several manners. One may choose to eject the fired case out of the same port from when it was loaded into an additional chamber. A second option is having the fired round exit the action via a mini port machined into the action opposite the loading port. This ability of having the round ejected from the action mechanically, instead of manually, greatly improves the shooters concentration and ability to finish a group in the same set of conditions prior to a major wind change taking place.

For those of you unfamiliar with the world of benchrest shooting ”Urban Legends”, the story goes like this: Once every so many years, the Gods of Wind who preside over the ranges where mortal men gather to shoot forge from the furnace of ”Crucible” steel a single bar of stainless steel. This bar is like no other. The gods of rifling are then called from the far corners of the country: Texas, Wisconsin, New York, all to impart the most perfect rifling of their craft into this gleaming piece of steel. It is done. The ”HUMMER” again exists in the universe. The gods have one final task and that is to cast lots in order to finalize who will wield such a powerful tool. Those few men who have been blessed by the BR gods have told many a tale of the almighty ”HUMMER” barrel: one can virtually do no wrong out in the midst of their competitors. It is also said that he who possesses such a barrel could sit at the bench and shoot through changing conditions. The possessor, it is told, can also pull the trigger in a complete 180 degree switch and have the bullet move only slightly, barely enlarging ones group. In addition, granted to its owner is the power over all bullets and powder. The ”HUMMERS” are known to shoot any and all powder and bullet combinations virtually through the same hole. The above story is TRUE. Your writer has on three occasions been in possession of a ”HUMMER”. Some of the names have been changed though to protect the innocent. Stepping back into reality, the choice of a barrel can be made very simply by following the match equipment reports posted in several publications. Names like Shilen, Hart, Krieger and Broughton are synonymous with World Record setting accuracy. Once you have chosen a maker, always select the slowest rate of twist per the given bullet you have chosen. This allows you to spin the bullet fast enough to stabilize it, yet not throw a bad bullet too far out of the group due to over stabilization. Secondly, choose a barrel length no longer than needed to produce the velocity you are trying to achieve. This will allow maximum stiffness of the barrel insuring the greatest accuracy potential. Today you will see many fluted barrels making their way onto the scene. The advent of the new, heavier, higher magnification scopes has caused some rifle owners to look towards barrel fluting to lose a little weight. Fluting a barrel has three advantages: 1) Fluting easily reduces weight without trying to skeletonize and change parts. 2) Fluting increases the surface area of the barrel, allowing for faster cooling. 3)Fluting just looks cool! If you can’t shoot well, at least look good doing it! Barrel Finishes In the process of firing a group, our barrels begin to absorb heat from the bore and radiate it from the surface of the barrel as it cools. Unfortunately for the shooter, as this process takes place, the reflected light from the target must pass directly over our heated barrel and into the objective lens of our scope. Well, no lesson in physics is required here. As we try to continue our group, we repeatedly return our gun to battery at a point in space that may or may not be our actual aiming point. We can say good-bye to any chance of a good group under these types of conditions I would suspect. As we return to our original subject ”Barrel Finishes”, there are two basic finishes that are normally seen and a new to the market, Trade Marked ”Spyder-Web” finish that is now offered by Speedco Shooting Sports. The two basic finishes commonly seen on benchrest and target rifles are the standard bright polish and the matte glass beaded finish. The bright polished finish is attractive to the eye but has the highest retention of heat thus interfering with the optical sight picture for a longer period as the barrel cools. The matte glass beaded finish cools the barrel at a much greater rate because of the thousands of micro-dimples formed on the surface of the barrel when struck by the glass spheres. This process, like fluting, also increases the surface area of the barrel. The micro-dimples diffuse the radiated heat into many different directions thus minimizing the heats effect on our sight picture. The ”Spyder-Web” finish combines both esthetic beauty and function making it probably the most desirable finish of the three. While its application process is guarded, a picture in this case is worth a thousand words.

The modern benchrest stock is typically constructed from a lightweight composite material with enough strength and backbone to support the weight of the other components yet meets the weight requirements of the finished rifle. Material selection for stocks varies from maker to maker. Some choose to use the time proven fiber-glass with polyester resin, others a blend of fiber-glass and carbon fiber and still others rely solely on pure carbon-fiber with epoxy resins to bind the matrix for the utmost in rigidity.

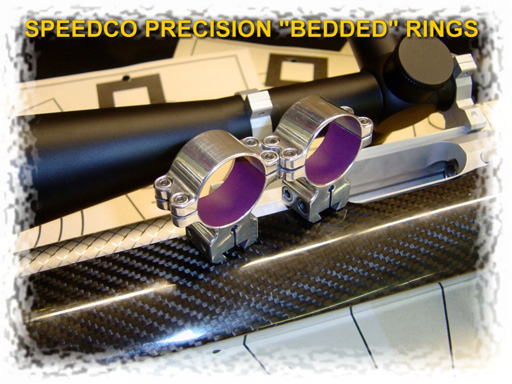

You will find many disagreements among shooters as to which is the better material. However, to date they have all proven to be competitive at one time or another. The most important job of a stock is to track in the bag! When this criterion is not met, all bets are off. The task of shooting a good group now becomes a laborious job of positioning and repositioning the rifle from shot to shot. The stocks second most important function is to maintain its contact with the sandbag. This is to say that under recoil we do not want to see the rifle torqueing or jumping out of the bag as it slides to its rearmost position. Ideally, as the rifle is fired, the stock tracks straight back into the shooters shoulder. These two functions are primarily the result of a properly designed stock with these results in mind. Lastly, a knowledgeable riflesmith with experience as to how a stock is set up to track correctly is advantageous. These topics will be discussed in more detail later in our ”Accuracy Tips” tips section of the manual. Regardless, the scope is the shooters link between themselves and the target. This being the case, the benchrest target scopes must be capable of achieving several things. It must have the ability to place the scopes reticle on the target, exactly in the same place, time after time. This requires the scopes internal design to be mechanically sound and devoid of any movement whatsoever.

Next, the competitor must have a scope with magnification great enough to section a bullet hole at 100 yards into four pieces. The current trend of commercial benchrest scopes, range in power from 36X to 45X, have the ability to do just that. Finally, the scope must have provisions to effortlessly make corrections in parallax. This allows the shooter to retain the clearest sight picture with no apparent optical movement of the reticle on the target. This also allows the shooter to adjust the scope for slight yardage errors from range to range. Here as in other parts of the rifle that have been discussed, the way the scope is mounted to the rifle has much to do with how well the rifle will function as a whole. As with the stock, if the rifle is going to be setup correctly to track, the scope must be setup in a particular manor. This will also be described in detail in the ”Accuracy Tips” section of Xtreme Accuracy Shooting.

While all bags available on the market have the potential to fill the shooters needs, filling the bags with the correct media greatly effects the way certain stocks ride within the confines. Too hard of a set up leads to the rifle bouncing or deflecting off the surface while on the flip side of the coin, too soft and the bag will allow itself to deform and loose its shape under the force of the rifles recoil. (See tips for properly filling and tuning sandbags in the ”Accuracy Tips” section.)

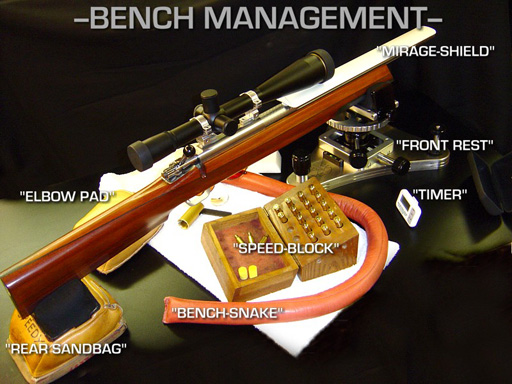

There are also other leather bags available to aid the shooter. One set of such bags is designed to be placed under the elbow in order to keep the shooter from being skinned up during recoil. Another similar bag can be placed under the palm of the hand to help support the hand when shooting free recoil. Two other types of bags that should be monitored are the so-called ”RING” or ”STABILIZER” bag. This is a rectangular bag filled only around its edges. It is used to contain the rear sandbag and keep it from rocking under recoil. The last is called the ”SNAKE”. This is a cylindrical bag about 24″ long and about an l½” in diameter. Its purpose is to confine ejected brass to an area on the bench top and keep it from rolling off onto the concrete below. 8. BENCH ACCESSORIES The items are listed below with a brief description of their intended use. Please note the word ”intended”. They are not intended to be used as objects with which to vent ones frustration at the range, especially when you have four shots in one hole and the fifth one is sitting all alone like a satellite orbiting the earth. Many good men have picked up their favorite cartridge box, called it by a name other than that given to such an accessory, and hurled it down range hoping to appease the lords of the wind. The Timer Cartridge Box or Block

Bolt Lube Bolt Disassembly Tool Small Hand Towel Wind Flags The wind flag becomes the competitors visual reference of the dynamics taking place between the bench and the target. Of all the skills you will acquire in the sport of benchrest, the ability to read the wind is the single most important skill of all. It is also the most difficult to master. Like many other aspects of this sport, there is no such thing as a standard wing flag. Most novice shooters attend several matches and get a sense of what type of flag appeals to them. Size, shape and color are left to the competitors imagination. Once a flag has been selected, it is common to have at least a set of four flags for the 100 yard stage and six for the 200 yard stage. How the flags should be set depends on the shooters ability to see them as he is looking through the scope at the target. (See ”Accuracy Tips” for detailed methods of setting your wind flags). The Adjustable Shooting Stool Ranges across the country are not held to any standard where bench dimensions are concerned. The consequence is the active competitor is faced with a wide variety of bench tops and heights. Bearing in mind, that comfort behind the rifle is paramount to shooting small groups, the ability to adjust ones height and position at the bench become very important. This is where the adjustable shooting stools ability to situate the shooter in exactly the right position, makes it one of the most valuable tools at the bench. Reloading Equipments Reloading equipment for the sport of benchrest has evolved into a highly specialized group of tools. The art of loading some of the most accurate ammunition in the world hinges on the remarkably close tolerances held on the custom tools built for the sport. When a new shooter visits a benchrest match for the first time the reloading equipment he is exposed to, is reminiscent of watching NASCAR mechanics assembling one of their high performance engines. The list of tools featured below will allow the benchrest competitor to load finished rounds that will hold tolerances to less than l/10,000th (one ten thousandth) of an inch when he/she does their part. 9.CUSTOM FULL LENGTH/BUSHING SIZE DIE

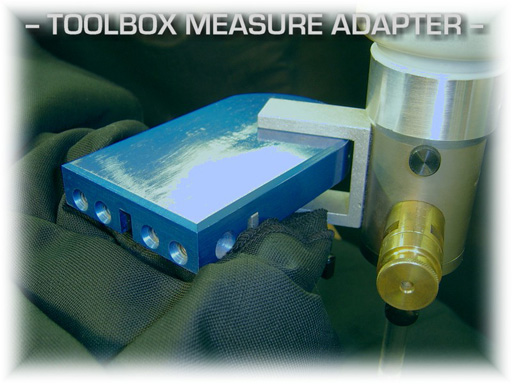

The old myth that neck sizing produces the best accuracy, has proven to be just that. Tony Boyer has 98 Benchrest Hall of Fame points, nearly twice as many as the gentleman in second place. All of these points were garnered while using the full length/bushing type size die. Another feature of the custom FL / Bushing type die is the fact that most are machined using matching reamers to the chambers in the rifles the dies are built for. Many shooters attach outriggers to their toolboxes in order to mount their powder measures. Many frustrated machinists spend hours building chests that resemble works of art and are actually almost too beautiful to use.

Size is governed by the amount of goodies you own or how strong a back you have. Just remember that half the fun of benchrest is the accumulation of all the gadgets required to fill your box. It is always more fun to be the envy of the range when you open your box revealing all the sparkling trinkets hidden within.

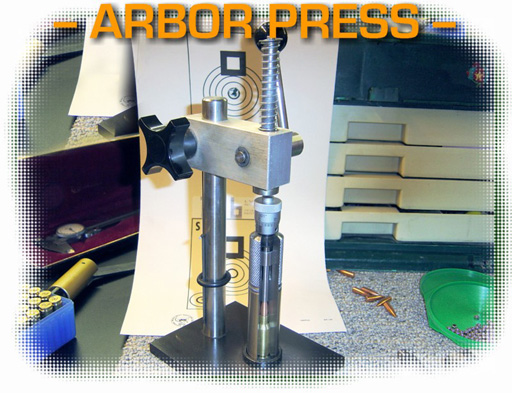

The other requirement was for the press to be compact, light and portable. Once these criteria had been met, the competitor now has the ability to begin the procedure of building some of the highest quality ammo in the world. This press, coupled with the full length / bushing die, set the shooter at the leading edge of reloading technology.

The straight-line bullet seater die is no exception. The die is chambered with the exact same reamer as the chamber in your rifle. This ensures the competitor that when the bullet is seated into a sized, charged and primed case, it will be in as perfect alignment with the corresponding chamber in his/her rifle as possible. (For instructions on the proper use of this type of die, see our ”Accuracy Tips” section).

It is used mainly in the process of giving the benchrest reloader the needed mechanical advantage when seating his/her bullets into the case necks. Due to its size, the arbor allows the reloader to actually feel the bullet as it enters the case mouth and feel slight variation in looseness or tightness of the neck on the bullet. This allows the reloader to possibly cull a bad round out of his block before shooting it at the target to ruin a winning group. The piece of barrel steel is first machined true and set up in the lathe as if to chamber a barrel. The reamer is then run into the barrel stub to almost the point where the body and shoulder meet. Voila! We have our gage. With this new tool we can now measure our bullets seating depth, the amount of shoulder set back and other things we will get into in the ”Accuracy Tips” section.

All benchrest powder measures are made up of three primary units: the body, the drum and the baffle/bottle adapter. The Body The Drum The Baffle/Bottle Adapter

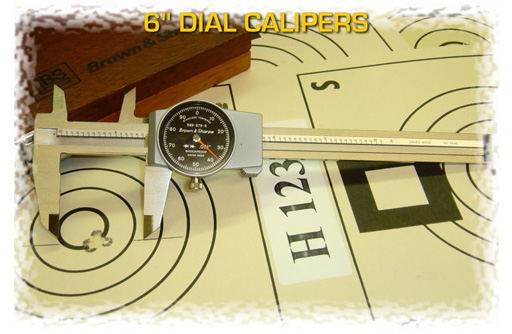

Three tools will be required to perform 99.999% of the measuring needed for benchrest competition. A good set of 6 dial calipers, a l micrometer with l/l0th of a thousandth vernier scale, and a l ball or tubing micrometer also with l/l0th of a thousandth vernier scale. Several top name brands such as Browne & Sharp, Starrett, and Mitutoyo are available from most commercial machine tool supply houses. Once acquired, these instruments will be used to measure everything from overall cartridge length to the thickness of the neck walls of your brass.

A simple solution to this problem is achieved by the use of a carbide tipped tool known as a ”primer pocket uniformer”. The uniformer consists of carbide, bottom-cutting blade ground to a specific depth with a knurled steel handle. It is designed to be used by hand by placing it into the primer pocket of a cartridge case and then turning it clockwise until the pre-set depth is reached. The results will be all cases having identical depths in their primer pockets.

The same tool can now serve a second purpose once the uniformed brass has been shot and then again resized and de-primed. The uniformer can be employed to remove the carbon buildup in the primer pockets after the round has been fired.

Most benchrest case trimmers are very simple devices. For anyone with any machining experience, you will soon realize the case trimmer is actually a small hand driven lathe. It has a small bed with two ways that align the case holder with the main cutting head. Like a lathe, the rear portion of the trimmer has a screw similar to the spindle in a lathes tailstock. This is used to determine how much metal will be removed by the cutter head. Some of the higher priced case trimmers have actual micrometer heads built into them, taking all the guesswork out of the operation. The case trimmer will become an invaluable tool to any benchrest shooter on the quest of making the perfect loaded round.

Bullet pullers are used to remove bullets from loaded rounds or to move a bullet further out of the neck when testing for proper bullet seating depth. The bullet puller itself is machined with handles like a pair of pliers. The upper half has a series of holes precision drilled and reamed to accommodate several common bullets diameters. The upper half is then split allowing the operator to squeeze the handles and grasp the bullet. A few half turns of the bullet is usually enough to free it from the case. Loading Block – Typically a small machined piece of plexi-glass, wood or Delrin. Its purpose is to hold 20 to 25 cartridges in place as the loading process takes place. Case Neck Brush – The case neck brush is designed to remove carbon build up inside the neck. The brushes are usually made from hard nylon or bronze. Some argue the nylon is best for the job because the bronze brushes tend to shed their bristles as they become worn. Iosso has just introduced a new heavy bristle nylon brush to the market that may prove to be the best of both worlds.

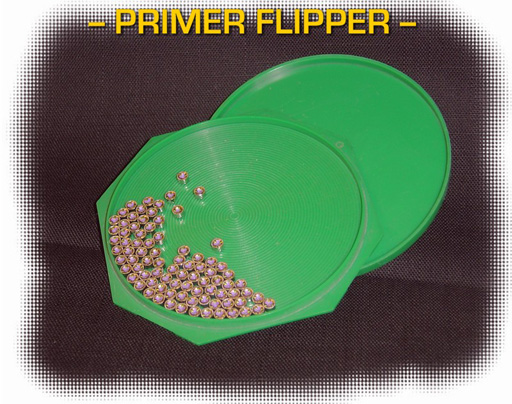

Primer Flipper – This is a very handy tool. It has the ability to orient all of your primers in one direction at one time. This will greatly improve your speed by eliminating the need to orient each primer by hand as they are seated into the case.

Primer Seater – Manufactured by several companies, the basic tool designs are nearly identical. The purpose of the benchrest primer seater is to hold the case squarely against the shell holder and seat a primer to a uniform depth below the head of the case. It accomplishes this task through its use of a two piece sleeved ram. As the handle is squeezed, the spring loaded outer sleeve comes into contact with the head of the case and pushes it square with the inside lip of the shell holder. As the operator continues to squeeze the handle, the inner ram pushes the primer into the case head until it is seated correctly.

Neck Sizing Bushing – These are graduated rings of case-hardened steel or carbide used to resize the necks of fired cartridges. They are used in conjunction with the ”custom full length / bushing size die” to allow the shooter to fine tune the grip case neck on the bullet of the loaded round. The standard formula for determining the correct bushing diameter is as follows: (bullet diameter) + neck wall thickness per side x 2) – (0.0030 std. minimal neck size reduction) = standard nominal neck bushing size or: Bullet Diameter 0.2430 Wall Thickness x 2 + 0.0200 0.0030 Std. minimal neck size reduction – 0.0030 Standard nominal neck bushing size = 0.2600

Loading Table – While many ranges offer facilities from which to load and clean, it is sometimes better to carry your own loading table. This enables the shooter to begin a program that promotes a consistent methodology of procedures. Once the shooter begins to setup his equipment in a consistent manner, it will soon become second nature and much more of the focus can be channeled to the task of shooting tiny groups. Most loading tables are made by the competitors themselves. Legs can be purchased from any local hardware store as well as the plywood top. A common table dimension is 2 ft. x 4 ft. x ¾ to 1 inch thick. The benchrest round when broken down is comprised of four basic components: the case, the bullet, the primer and the powder. What makes these four components so different from normal ammunition are the tolerances to which they are held. The Case – When the competitor pulls the trigger and the firing pin slams into the primer, initiating the chain of events that will propel the projectile on its path to the target, the only reusable component remaining is the case. Because of its resilience, the brass (in benchrest terminology ”The Brass” is the nomenclature used to describe the case) and its ability to be reloaded repeatedly, is pampered and treated with kid gloves. It is actually possible to completely wear a barrel out (approximate match barrel life is 1500 rounds) with 20 pieces of brass loaded over and over again. This translates to each case being reloaded 75 times each. In benchrest shooting, the reigning king of cases is the 6PPC. The PPC is based on the Lapua 220 Russian case, co-developed by Ferris Pindell and Dr. Lou Palmisano. Since its inception in the mid 1970s, the PPC has yet to be rivaled in the field of pure accuracy potential. Its short fat design, coupled with an almost perfect case capacity to bore diameter ratio, make it one of the most efficient cases seen in the last 30 years. The 30-degree sharp-shouldered piece of brass provides a nearly perfect 100% powder loading density. The H.P. White Testing Laboratories accredited the features of the PPC to be the determining factors for the most uniform ignition, burn rate and pressure curves ever demonstrated in their facilities. Look for brass preparation techniques in the ”Accuracy Tips” section. The Bullet – No other component in the sport of benchrest has been as scrutinized as the bullet. For it is the bullets job to translate onto the target the shooters ability to perform his craft well.

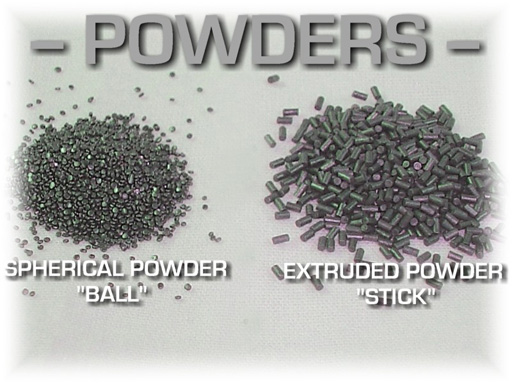

There is no commercial bullet to date that is capable of delivering the consistent accuracy needed to be competitive in the sport of benchrest. All benchrest bullets are made by hand, on a custom basis, with very limited production quantities. One of two bullet forms are currently seen on the firing line of todays benchrest shooting events. The first, and probably most common, is known as a ”Rorschach” shape. This is a bullet with a straight cylindrical body and a segment of a circle forming the point or ”OGIVE”. This bullet form is relatively easy to tune but can become very wind sensitive. The second bullet form is what Speedy Gonzalez coined the ”DOUBLE-RADIUS” bullet. This type of bullet has no straight cylindrical section to the body whatsoever. The 2R bullet form is actually two arcs from large radius circles becoming tangent to one another creating the bullets shape. When measured from the base, these bullets have a constant taper and the tangent point where body and ogive meet is virtually impossible to measure without the use of a CMM (coordinate measuring machine). Higher velocities and better wind bucking capabilities are attributed to this type of bullet form. The benchrest reloader is urged to try both types of bullet forms in every new barrel. Accuracy Powders – Present day smokeless propellants are classified into two groups, single base and double base. They are both primarily formulated from nitro-cellulose with the addition of nitro-glycerin to the double base for a higher energy yield. These powders are then divided into two groups according to their physical shape, either spherical or extruded cylinder. The spherical or ball powders are said to be easier on the barrel because of their cooler burning rates. They also meter through a powder measure like water making them easy to use when reloading.

The extruded powders are known for their ease of ignition. This is especially true in cold weather. As a competitor, it is to your advantage to be aware of these characteristics thus providing yourself with a better-rounded loading program. The ability to have an adaptive loading program is one of the secrets of the top-level shooters in this country. The Primer – Once considered insignificant in the equation of accuracy, the primer has now fallen under the microscope. No longer are these components, which costs less then $0.03 each, taken for granted. Benchrest shooters are now taking the time to check different lot numbers of the same brand as well as different manufacturers in an effort to wring the last bit of group shrinking magic out of their components. Primer selection and testing will be discussed in the ”Accuracy Tips” section of the manual.

Bench Management 101 As a competitor, you have been placed in charge of your own destiny. The final outcome of your efforts over the course of a one-day shoot, or a six-day National Championship match, depends on your ”management” of several key elements and yourself. So as not to complicate things, let us assume that you have arrived at a benchrest match with a well-tuned rifle and a winning attitude. You have paid your entry fees and drawn a bench assignment. From this point forward, your only task is to focus your attention and afford yourself every opportunity to win. How you accomplish this is very easy. By developing a goal oriented system of managing every aspect of your shooting program. Let us begin with the basic 5-point management plan. 1. The Range

The easiest method to managing your bench once the comfort factor is known is the ”Blind Man” method. Here is how it works. Step One – Carry all the necessary shooting equipment to the bench and the optional adjustable stool we discussed earlier, as well. Step Two – Lay out all of the equipment on the bench top within easy reach. Step Three – Close your eyes as if you could not see. Then, situate yourself on the stool where you feel most comfortable at the bench. Now with eyes remaining closed, reach out and start bringing your rear sandbag and front rifle rest and anything else you may manipulate on the bench closer or farther away from you, until they are all easily accessible without having to look at them. We are attempting to setup the bench in a manner that is within your personal and natural range of movement. Step Four – Open your eyes and take a mental snapshot of this arrangement. From now on every time you set up at the bench, you will attempt to duplicate this same set up and then perform the ”Blind Man” check to make certain it is correct. Step Five – Once we have setup our bench in a manner conducive to shooting comfortably, we next set our rifle in the bags and have a friend begin to set our wind flags out for us. Looking through the scope and starting from the targets back, we begin a setup that allows unrestricted vision of however many flags we decide to employ. The plan here is for the shooter to be able to multi-task with minimal movements, from observing the wind to making fine adjustments on his equipment prior to each shot.

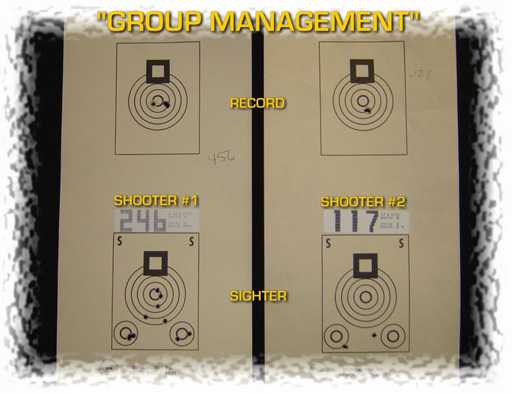

The 100-yard ”Two-Bull” benchrest target is a rectangular sheet, comprised of a record target and a sighter target stacked vertically. The lower sighter has three ½” ten rings printed on it, one main ring in the center and one in each of the lower corners, while the upper record target has only one in its center. The 200-yard target is identical in all respects with the exception that it is twice the size. Managing a target is a very easy concept to understand once it is explained to the shooter. As in life, we all pray for the best and plan for the worst. This becomes the premise for how we will learn to manage the precious few square inches of paper we are allotted on each target. Let us play out two shooting scenarios to help clear the murky waters. Benchrest shooter #1 goes to the line with 20 rounds of loaded ammo. The command to ”commence fire” is given by the range officer and our shooter fires his first couple of fouling shots (fouling shots are used to remove any residual cleaning solvents from the bore of the rifle barrel, prior to shooting a record group) into the lower left sighter bull. The shooter then moves over to the lower right sighter bull and tests the right to left wind with 2 or 3 shots. Liking what he sees, he attempts a 3 shot test group on the central sighter bull. Not bad, he thinks! Then he notices a reverse in conditions from left to right and shoots a couple more at the central sighter bull just to get a feel for what the full switch might be worth. The range officer gives the ”two minute” warning command, and our shooter goes up to the record target. His original right to left condition has returned, and he begins his group. After his fourth shot, the group appears to be little more than a 30-caliber bullet hole (this is referred to as a ”DOT” in benchrest lingo). With one minute left to go the wind dies off, he waits a few seconds for its return, but no luck. He decides to check where his rifle is printing the calm, by attempting a quick sighter shot. The range officer calls 30 seconds remaining. The shooter fires his sighter round at the central sighter bull and hits one of the previous holes used for testing. With time running out, he believes he knows which bullet hole it went into and holds his last record shot accordingly. ”Cease fire”, calls the range officer. The shooter looks through his scope with great hope, only to find disappointment seeing how the last shot is sitting completely out of the group. When the target is later posted on the Wailing Wall, the shooter sees that his last sighter had gone into an entirely different hole all together causing him to hold for his last shot in the wrong spot. Benchrest shooter #2 takes his 20 rounds of ammo to the bench, and the ”commence fire” command is given. He, like shooter #1, also takes a couple of fouling shots at the target. The difference being, shooter #2 wishes to keep his sighter target as free from extra shots as possible. Rather than using up any of the 3-sighter bulls, he elects to foul the barrel in the open space between the two lower bulls on the sighter. Shooter #2 has now fouled his barrel and still has 3 remaining bulls on which to shoot. Step one of the management process has begun. If you recall from earlier in our management program, we took a mental inventory of the predominant conditions on the range as well as the approximate duration of these conditions. Rather than testing every condition on the range let us select the most prominent condition with the greatest duration period for Shooter #2. We choose the same right to left condition as shooter #1. Then moving the scope to one of the bottom sighter bulls, we take one more look at the conditions, making sure it was the one we selected and take the shot. A bullet hole appears at 9 oclockon the bull. Rather than continuing to shoot, we take a moment to evaluate the shot. Shooter #2 decides the shot is in an acceptable location for the given condition and decides like #1 to stick with it. Shooter #2, unlike #1 does not fire a 3 shot test group using up valuable time and target space. Instead, #2 opts to fire a confirmation shot at the same bottom sighter bull as his previous shot. A confirmation shot is a confidence booster. The shooter takes in all the information provided to him, by sight, sound and feel. The shooter calculates in his mind when all is the same and pulls the trigger at just the right time. When the shot impacts the target in the expected location, the shooter begins to build confidence in his wind doping ability. With two-sighter bulls still left void of any sighter shots, the #2 shooter moves up to the record target. He looks over the range, waits for his condition to come back and begins his group just after the two-minute warning is given. After his third shot the wind on the range drops to a dead calm. You have one minute to complete your firing, calls the range officer. Realizing time is short, shooter #2 returns to his clean center sighter bulls, and shoots one last sighter. He sees the bullet impact has now moved directly under the intersection of his crosshairs. He moves quickly back to the record target, holds his last two shots directly over his first three shots and waits out the last few seconds of the match admiring the little dot he has just shot. As you can see, shooter #2s last two rounds were shot with a bit more confidence than shooter #1, since there was no question of where his last sighter shot impacted the target. Through better management of his target, shooter #2 turned a possible disastrous end into a possible win. he countdown timer becomes the shooters best aid in this instance. The timer, when set on the bench, keeps a constant vigil over the remaining time and with a glance, the shooter knows exactly how much time remains to complete his task. It has been observed at many matches: a shooter with no timer on his bench, goes into panic mode when the 2-minute warning is given. They have no idea of the pace the clock is counting down, and make decisions based on their feeling that time is running out. When in all actuality they wind up shooting a terrible group with a minute and a half left to go in the match and end up sitting at the bench staring angrily through their scope at the group that just cost them the match. The most common group you will see when a shooter snatches defeat from the hand of victory, is the dropped shot. This occurs when all your buddies and other competitors start the victory party a little ahead of your actually shooting that last world beating group. Your emotions takeover, as the pressure builds and your mind begins to scream ”YOU HAVE TO SHOOT A DOT HERE TO WIN”. The sad ending to this story is on Joe Shooters first chance to be a big winner, the fat lady decided to sing, hell froze over and pigs started to fly, and Joes last shot was sitting directly one inch under his group. Rather than sticking to the plan he had used all day and managed (theres that word again) to put him within arms reach of the brass ring, he rushed the last shot and jerked up on the trigger, sending that last shot down on the target. |

|||